Inside a vast 1890s-era factory in southern Massachusetts, just 15 workers remain, hunched over sewing machines producing specialized hospital-grade gear for newborns.

They are the last remnants of what was once a bustling manufacturing enterprise, most of which the Teixeira family shuttered in 1990 before shifting toward warehousing and distribution under the name Accurate Services Inc.

Since President Donald Trump began imposing broad tariffs, the family has received more inquiries from companies interested in reviving domestic sewing operations. But the Teixeiras have declined, citing hiring challenges tied to tighter immigration policies and skepticism about whether the surge in demand will last.

Their reluctance reflects the broader reality: delivering on Trump’s promised manufacturing revival is proving far more complicated than White House claims suggest.

“It’s just not going to happen,” said Frank Teixeira, who joined the family firm in the 1970s and later led its restructuring. “Tariffs are a bad policy, and eventually they’re going to come back to hurt us.”

Trump campaigned on the promise of economic renewal, pledging that tariffs would lower costs and spark a manufacturing renaissance. That message resonated with many voters, helping him gain traction in working-class communities that had long leaned Democratic—including Fall River, the Teixeiras’ hometown and once a thriving textile hub, where Trump became the first Republican presidential candidate in about a century to secure victory.

But economists criticized the plan from the outset, warning that tariffs—essentially taxes on imports—would drive up costs for U.S. businesses and consumers, slowing growth and especially straining manufacturers dependent on foreign materials.

Nine months into Trump’s presidency, as tariffs take effect, the gap between his upbeat rhetoric of surging investments and the day-to-day reality in towns like Fall River is becoming increasingly clear.

American manufacturer Matouk depends on imported fabrics and materials to produce luxury sheets, quilts, and towels.

Job growth in the U.S. has slowed sharply this year, particularly in manufacturing. After a period of post-pandemic expansion, factory payrolls are now shrinking—down by 12,000 positions in the past month alone.

Industry surveys also suggest the sector is contracting. In a recent poll by the Dallas Federal Reserve, 71% of manufacturers reported that tariffs—ranging from 10% to 50% on most imports—were already hurting their operations by driving up input costs and squeezing profits.

At Matouk, a luxury bedding manufacturer located near the Teixeiras’ business, CEO George Matouk said tariffs had increased expenses by more than $100,000 (£74,000) a month between April and August, with costs rising on imported supplies such as cotton fabric from India and Portugal and down feathers from Liechtenstein.

George Matouk reported that the tariffs have yielded nothing beneficial

Founded by his grandfather in 1929, the company has grown to employ roughly 300 workers in recent years—a source of pride for George Matouk, who overcame skepticism when he became the third generation to join the family business after earning his MBA from Columbia in the late 1990s.

However, the sudden financial strain from tariffs has forced the firm to scale back investments in areas such as new equipment and to curb discretionary spending, including marketing.

Even though many of its products carry a “Made in America” label, Matouk said the tariffs bring no advantages. Instead, the higher costs are driving him to raise prices, a step he fears will dampen demand.

“Because the materials are subject to tariffs just like everything else, the benefits are not there,” he explained.

Matouk described the situation as “demoralizing in a new way,” since the difficulties stem not from market forces but from government policy.

“We’ve done everything expected of us—investing in the U.S. industrial base when few others were willing—and now it’s incredibly frustrating to find ourselves being punished for it,” he said.

Kim and Mike van der Sleesen, owners of Vanson Leathers

Research on the limited tariffs implemented by Trump during his first term suggests that small job gains in protected sectors, such as steel, were outweighed by losses at companies reliant on imported parts.

Mike van der Sleesen, who runs the motorcycle jacket company Vanson Leathers, said this year’s changes have been so disruptive that it’s too early to predict their full impact.

Although he voted for Trump last year, van der Sleesen is critical of the president’s tariffs, which have increased his costs by roughly 15% this year.

At the same time, he echoed Trump’s concern that foreign companies can more easily access the U.S. market, while American businesses face barriers like tariffs and other taxes when selling abroad.

One of the roughly 50 workers at Vanson Leathers

“It’s been a very uneven and unfair trade environment for a company like Vanson,” said Mike van der Sleesen, whose business was founded in 1974. The company once employed over 160 people in 2000, but China’s entry into the global market cut the workforce to around 50.

“We shouldn’t be taxing them, and they shouldn’t be taxing us—but that’s never going to happen,” he added.

For now, demand for his high-end jackets, which can sell for thousands of dollars, remains strong, and U.S. suppliers are seeing increased activity.

“We haven’t seen overtime in the textile industry for 20 years!” he said. “It’s difficult to predict how things will turn out because the changes have been so dramatic.”

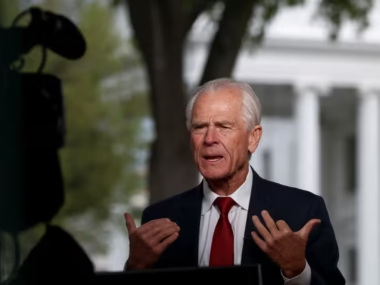

Retired transit worker Tom Teixeira believes it will take time for things to improve

On the streets of Fall River, many Trump supporters said they were willing to give the president time to see his policies in action.

“We should be able to manufacture,” said Tom Teixeira.

The 72-year-old retired transit worker, who voted for Trump in 2016, 2020, and 2024, was drawn in part by the president’s economic message.

“I know how it used to be, and it can get better, but it won’t happen overnight,” he said, noting he hadn’t noticed significant price increases this year.

“A year from now, if things aren’t cheaper, we’ll see.”