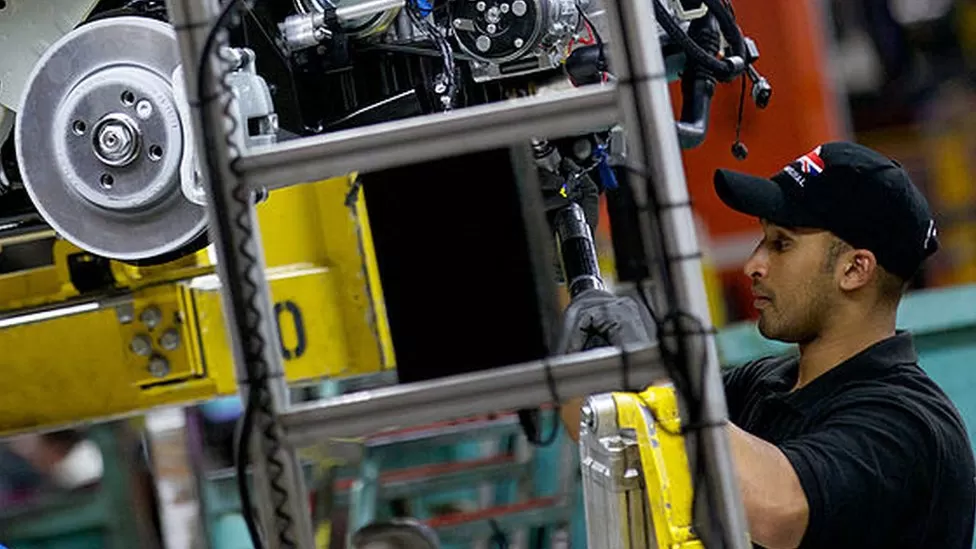

BMW, the world’s largest automaker, has stated that it will spend hundreds of millions of pounds preparing its Mini factory near Oxford to produce a new generation of electric vehicles.

At the Cowley factory, two new electric Mini models are scheduled to go into production in 2026.

The change is anticipated to secure the facility’s viability as well as the future of another business in Swindon.

At the moment, more than 4,000 people are employed by the two locations.

BMW will invest £600 million in upgrading the Cowley facility, expanding its body shop, and constructing additional areas for installing batteries.

Additionally, it has plans to expand the Cowley and the Swindon factories where body panels for new cars are produced.

This will enable Cowley to produce both conventional vehicles and two next-generation electric models, the Mini Cooper and the bigger Mini Aceman.

The Countryman, a third electric vehicle, will be produced in Germany.

The UK investment will be supported by government funds, estimated to be worth £75 million.

The announcement was referred to as a “vote of confidence” in the nation’s automobile manufacturing sector by Mike Hawes, chief executive of the UK industry group the Society of Motor Manufacturers and Traders.

It not only ensures the long-term viability of the region that is home to one of the most recognizable companies in the world, but it also highlights our strengths in the production of electric vehicles, he added.

“Investments like this increase productivity and aid in generating jobs, economic growth, and benefits for the nation.”

• Is the UK on track to reach its net zero goals in terms of climate change?

• The ‘UK’s largest’ EV charging point launches at the NEC.

• Production of electric vehicles begins at a unique plant.

The future of the two UK facilities depends on BMW’s decision because the Mini brand is anticipated to go all electric by 2030.

2019 saw the Cowley facility introduce the first electrified Mini.

However, the corporation said last year that manufacture of the majority of its electric vehicles would relocate to China, where the new models had been created in collaboration with Great Wall Motor.

BMW said that it was inefficient to produce both conventionally fueled and electric vehicles in the same factory at the time.

This strategy has obviously changed since then.

The new models will be produced starting in 2019 at Great Wall’s factory in Zhangjiagang; Cowley is now anticipated to begin producing them in 2026.

BMW’s investment, according to Prime Minister Rishi Sunak, is “another shining example of why the UK is the best place to build cars of the future.”

Business Secretary Kemi Badenoch said to reporters when asked about reports that BMW received roughly £75 million in government financing for its Oxford plant: “I won’t comment on the figure because that creates difficulties in future negotiations.

“What I will say is that because the auto industry experiences so many challenges, some of which are regulatory in nature, we do provide very minor subsidies to it.

Therefore, if we urge manufacturers to switch to net zero, that generates additional expenses and makes it a little bit harder so we do have to take that into account.

This is the most recent in a line of government-sponsored projects aimed at advancing the manufacture of electric vehicles in Britain before a ban on the sale of new gasoline and diesel vehicles is set to go into force in 2035.

The Indian company Tata, which owns Jaguar Land Rover, said in July that it would construct a sizable “gigafactory” to create batteries in Somerset. The project is anticipated to get hundreds of millions of pounds in taxpayer subsidies.

In Cheshire, Stellantis has just started making electric vans at its Ellesmere Port facility. Nissan is increasing production of EVs at its Sunderland facility, and its partner Envision AESC is constructing a gigafactory nearby.

Ford is also making significant investments in its Halewood facility to get it ready to produce electric motors.

However, there have also been setbacks for the sector in recent years, such as the closure of Honda’s Swindon factory in 2021 and Ford’s Bridgend engine plant in 2020.

Britishvolt, which had intended to construct a battery manufacturing close to Blyth, entered administration in January. The site’s future is still up in the air.

Professor of business economics at Birmingham Business School David Bailey told the BBC that while the BMW announcement was “great news,” the UK was still catching up.

We haven’t been producing enough electric vehicles. If we want to keep the UK’s mass-car sector alive, we’re going to need a lot more.

Where the batteries for the cars to be constructed in Cowley will come from is still a mystery.

That might still develop into a serious problem. New regulations will make it such that vehicles with batteries built outside of the EU or the UK will be subject to high import duties beginning the following year.

BMW is one of many companies that have lobbied the EU and the UK to delay or weaken the regulations.

According to the Brexit trade regulations, there will be a 10% levy on commerce between the UK and the EU if automobiles don’t contain enough local content, according to Prof. Bailey. “Well, that’s obviously a significant hit for companies like Stellantis and BMW. That needs to be changed right away.

He continued by saying that there was a lot of pressure “on both sides of the Channel” to alter the trade regulations. “I anticipate some action from the European Commission, but probably too late.”